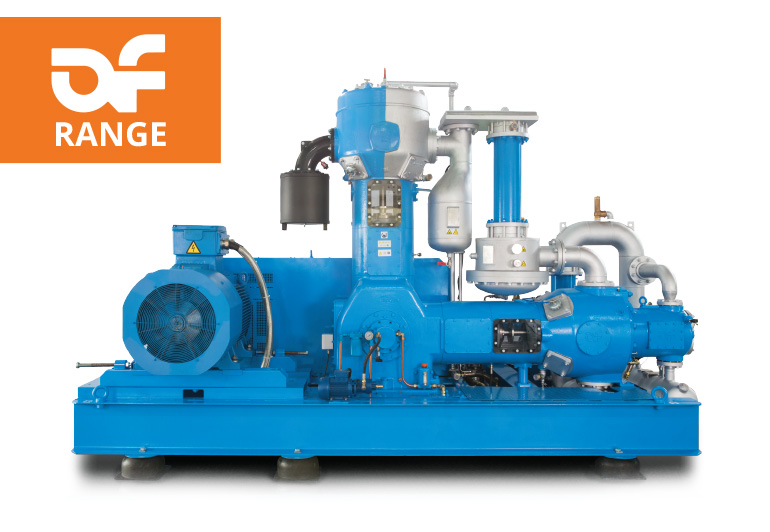

The 40 bar oil free PET compressor range from 225 m³/H to 3200 m³/H.

AF suits to the basic ISO 8573 Class 1. rule, and in addition, offers a 40 bar stainless steel refregerative air dryer with 3°C dew point. The dryer is equipped with dew point alarm, integrated 1µ filter and integrated automatic draining system. Stainless steel condenser and optional additional active carbon filter will complete our standard 40 bar PET packages to supply the best air quality on the PET market. The 40 bar compressed air package is mounted on a base plate equipped with anti-vibration mountings and includes:

Electric motor from 55 to 550 kW and V-belt transmission, V-Belt drive system complete with sheet steel guard and inspection door. The system allows the compressor speed to be adapted to give precisely the required Free Air Delivery. Standard range design for optimum efficiency. intercoolers between each stage and after-cooler.

Three stage “L” cylinder compressor with :

3 micron air inlet filter suitable for dusty conditions. Supplied with filter condition indicator.

Intake and discharge valves made from 100% stainless steel.

Piston rod packings with PTFE seal rings.

Gear type oil pump driven by crankshaft.

Oil filter rated for full flow and cleanable while running.

Shell and tube type water-cooled intercoolers and aftercooler with removable tube bundles for cleaning.

Galvanised moisture separators on each stage with safety valve and automatic drain trap, Bekomat drain system fitted on 2nd stage.

Nickel plated or galvanised interconnecting air pipework.

Thermostatic water valve to maintain ideal operating air temperatures with in cylinders.

Locally mounted temperature and pressure gauges with transmitters and switches to provide safe and efficient operation in conjunction with the microprocessor located in the Electric motor suitable for power supplies from 400v/3ph/50Hz to 460v/3ph/60Hz. Class F insulation and protection to IP23, others on request. Motor mounted on slide rails for belt tensioning.

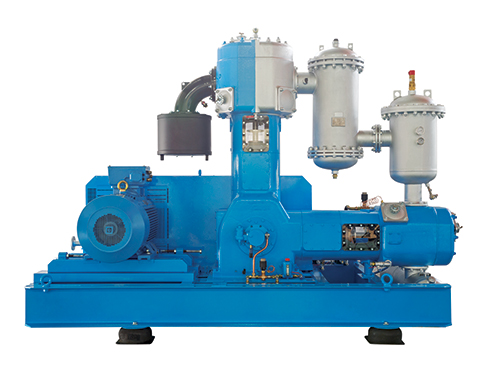

OPC 7 & 10 bar. Oil free two stage piston compressor range from 7,7 to 54,5 m³/min ( 6 to 15 bar possibilities on request)

Oil free 2 stage piston compressor OPC 7 & 10 bar.

Oil free two stage piston compressor range from 7,7 to 54,5 m³/min

( 6 to 15 bar possibilities on request)

Oil free 2 stage piston compressor Simple & efficient design

The OPC air compressor solution is a heavy duty, low speed, two stages, oil free, water cooled, reciprocating unit with an “L” cylinder design.

The 6-15 bar oil free piston compressor is mounted on a base plate equipped with anti-vibration mountings and includes:

Electric motor and V-belt transmission,

Intercooler between the stages and after-cooler,

The control cabinet with microprocessor is installed adjacent to the base plate.

Compressor base-plate with anti-vibration mounts. No special concrete foundation block is required, resulting from the use of anti-vibration mountings. Easy and quick installation.

2 stage ‘L shape’ cylinder compressor:

Design on AF RANGE bare units

5 micron air inlet filter suitable for dusty conditions. Supplied with filter condition indicator.

Intake and discharge valves made from 100% stainless steel.

Piston rod packings with PTFE seal rings.

Gear type oil pump driven by crankshaft.

Oil filter rated for full flow and cleanable while running.

Shell and tube type water-cooled intercooler and after-cooler with removable tube bundles for cleaning.

Galvanised moisture separator between the stages with safety valve and automatic drain trap.

Nickel plated or galvanised interconnecting air pipework.

Thermostatic water valve to maintain ideal operating air temperatures within cylinders.

Locally mounted temperature and pressure gauges with transmitters and switches to provide safe and efficient operation in conjunction with the microprocessor located in the control cabinet.

Electric motor suitable for power supplies from 400V/3ph/50Hz to 480V/3ph/60Hz. Class F insulation and protection to IP23/55, IE2, IE3…on request. Motor mounted on slide rails for belt tensioning.

Common base plate supported on anti-vibration mountings for the above mentioned equipment. No special foundation is required.

V‑Belt drive system complete with sheet steel guard and inspection door. The system allows the compressor speed to be adapted to give precisely the required Free Air Delivery.

Standard range design for optimum efficiency.